A client had inquired about making repeated wand passes on heavily soiled carpet and concerned that it might over-wet the carpet.

He stated the first and second pass did not properly clean the carpet, and the recovery water was still dark. His apprehension was in using multiple passes that would produce subsequent wicking of soil especially on light colored carpet.

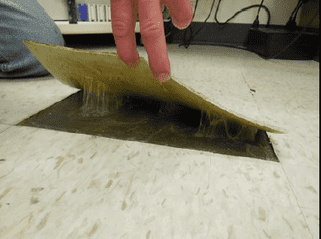

Over-wetting a carpet normally does not show the effects until capillary action has taken its course over the next 24-48 hours. The problem does not surface until later, when wicking produces a dingy appearance on the finished carpet.

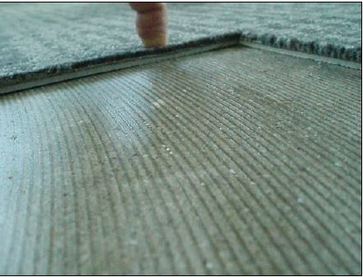

No one likes to re-do jobs, and it calls a technicians reputation into question. On a heavily soiled carpet you normally have no choice but to go over it several times to get it clean. The way to extract a higher percentage of the soiled solution from the carpet is to apply pressure on the wand to force it deeper into the carpet nap. Only trigger the wand as you pull it back towards you, and then follow the same path while pushing it back to the start position and applying constant pressure.

When multiple passes are required, set a carpet dryer immediately after cleaning a room or after cleaning about 200 sq. ft. You can also consider using a dry bonnet on a floor machine or buffer to absorb as much moisture as possible. This must be accomplished immediately behind extraction, before the carpet begins to dry. The process normally speeds the drying time by 30-40%. Make sure that bonnet cleaning is approved by the carpet manufacturer.

Another helpful cleaning tip is to ensure the pre-spray and pre-scrub is sufficient to emulsify and pre-dissolve the soil. Remember, the wand or extraction head is a rinse tool and meant to flush loosened soil.

Even a rotary extractor can be used to pre-scrub by removing the vacuum hose and not triggering the rinse valve until the carpet has been scrubbed with at least one pass over the entire area. It is normal to observe at least a 75% appearance improvement with the pre-spray and scrub operation. Then you know the carpet is now ready for the flushing action.

Rework and call-backs are no fun. Training efforts pay off through regular and repeated educational instruction.

If you need a program for in-house training of your cleaning technicians, follow this link and check out the Carpet and Floor Care Training Bundles. There is a video that explains it all on that page.

Gary Clipperton is a 45-year industry veteran and author of several books, training programs, software and videos. His new training program includes a carpet startup and expansion program, IICRC Basic Skills Carpet Care program, and Cleaning Managers Dashboard all in the new Carpet and Floor Care Bundle available through Totally Booked University. Gary can be reached at [email protected] or 719-598-5112.